A snatch block changes how force is applied in a winching system. By routing the winch line through the pulley and back to a vehicle or anchor, it redistributes the load, reduces the winch’s workload, and maintains vehicle movement.

In UTV recovery, snatch blocks serve two main purposes: changing direction and reducing load. Directional changes enable safer anchor placement, while load reduction distributes resistance, lowering strain on the motor, solenoid, wiring, and mounting points.

A snatch block does not increase pulling power but improves winch efficiency under load. It is a key component in system-based recovery, where technique and load management protect equipment and occupants.

When used correctly, a snatch block increases control, reduces heat buildup, and minimizes electrical overload risk. These benefits apply to any winch size or capacity.

Jump To Contents

- Key Components of a Snatch Block System

- Why Snatch Blocks Matter in UTV Recovery

- Mechanical Advantage Explained (Without the Math)

- How Snatch Blocks Reduce Winch Load and Electrical Strain

- When You Should Use a Snatch Block During UTV Recovery

- When a Snatch Block Is NOT Necessary (or Can Be Misused)

- Snatch Block Safety Rules Every UTV Owner Should Follow

- Common Snatch Block Mistakes That Cause Equipment Failure

- Snatch Block or Bigger Winch: Which Truly Enhances Your UTV Recovery?

- Snatch Blocks as Part of a Complete Winch Recovery System

- Frequently Asked Questions About Snatch Blocks

- Final Takeaway

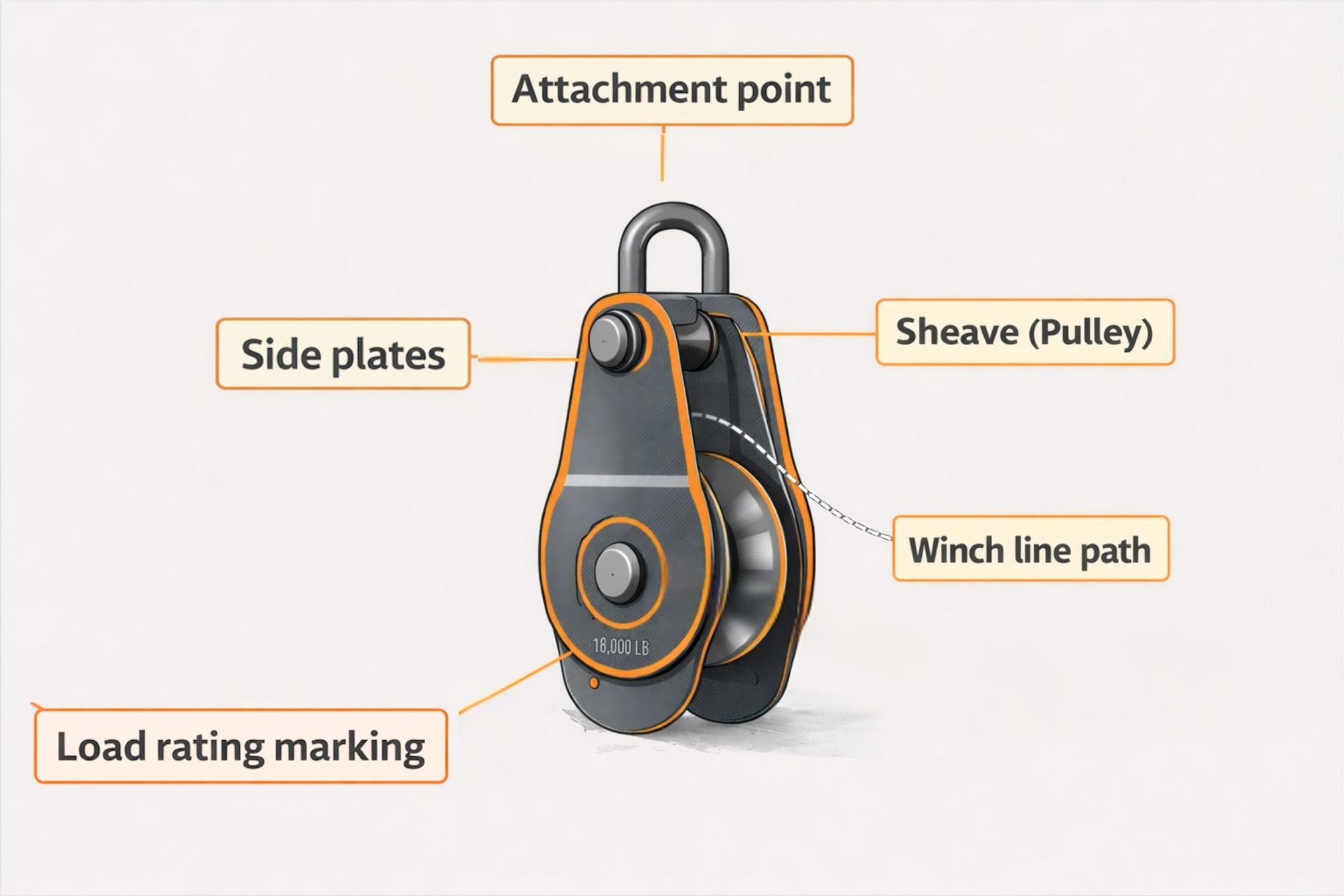

Key Components of a Snatch Block System

A snatch block system includes a load-rated pulley, reinforced side plates, and a properly routed winch line to manage force, friction, and load distribution during recovery.

Pulley Wheel (Sheave)

The pulley wheel, or sheave, is the rotating part that lets the winch line move under load with less friction. A smooth, properly sized sheave limits heat buildup and prevents rope or cable abrasion during pulls.

Sheave diameter and material directly affect efficiency. Undersized or poorly finished pulleys increase friction, transfer heat to the rope, and reduce mechanical advantage.

The pulley itself is only one part of the equation, and its effectiveness depends on how it works alongside other essential winch recovery accessories used during safe recoveries.

Side Plates and Load Rating

Side plates support the pulley and contain the recovery load. Each snatch block is rated for a specific working load, which must meet or exceed the forces generated during winching, not just the winch’s advertised capacity.

Underrated side plates can deform or fail even if the winch operates within its limits. In system-based recovery, the snatch block rating is as important as the winch rating, since the pulley often experiences forces equal to or greater than the winch line.

Winch Line Path

The winch line path determines how force is redistributed. In a double-line setup, the line runs from the winch, through the snatch block, and back to the vehicle or anchor. This routing reduces load on the winch motor and increases control.

Incorrect routing, such as misaligned angles or rope contact with side plates, reduces efficiency and increases wear. Proper line-path setup is why snatch blocks are part of a complete winch recovery system, not just a standalone accessory.

Line routing affects more than efficiency, because the way the line enters, wraps, and exits the pulley changes depending on how synthetic rope and steel cable behave under load.

Why Snatch Blocks Matter in UTV Recovery

Reduced Mechanical and Electrical Stress

By lowering the load on the winch, a snatch block reduces stress on the motor, gears, and mounting points. This decreases amp draw from the battery and stator, helping prevent voltage drop, solenoid overheating, and early winch failure.

Improved Control in High-Resistance Terrain

In mud, snow, or on steep inclines, resistance can increase unpredictably. A snatch block slows the pull while maintaining force, reducing shock loading when suction breaks or traction changes. This results in a smoother, more controlled recovery.

Increased Safety Margin for Equipment and People

Lower line tension at the winch reduces the system’s stored energy. This minimizes the severity of recoil if a component fails and makes recovery safer for bystanders and operators.

Operator control plays a role here as well, since maintaining distance from stored energy depends partly on the ability to control the winch from a safer position.

Better Use of Existing Winch Capacity

Instead of relying on maximum pulling power, a snatch block lets a properly sized winch operate within safer limits. This supports a system-based recovery approach, where technique and load management extend equipment capability without upgrading winch size.

A snatch block helps the winch work more efficiently under stress, especially when electrical capacity, not pulling power, is the limiting factor.

Mechanical Advantage Explained (Without the Math)

Mechanical advantage in winching is achieved through pulley geometry, which reduces the load on the winch by distributing resistance across a greater length of the winch line.

Mechanical advantage is the core reason a snatch block works. Instead of the winch pulling against the full recovery resistance directly, the pulley system redistributes the force along the winch line. This lowers the effective load on the winch motor while still moving the vehicle.

In practical UTV recovery, mechanical advantage is not about increasing strength; it is about reducing strain. The winch performs the same task with less effort, protecting both mechanical and electrical components.

Single-Line Pull vs Double-Line Pull

Single-line pull (no snatch block)

The winch line runs directly from the winch to the vehicle or anchor. The winch motor, battery, and electrical system absorb the full recovery load.

Double-line pull (with a snatch block)

The winch line is routed through a snatch block and redirected back toward the vehicle or anchor. This configuration reduces the load seen by the winch, even though the vehicle still moves against the same resistance.

A double-line pull can reduce winch load by nearly half, while also improving control and reducing sudden force spikes.

What Changes—and What Doesn’t

What changes

- The load on the winch motor is reduced.

- The pull becomes slower and more controlled.

What doesn’t change

- Vehicle weight and terrain resistance remain the same.

- Mud suction and incline forces still apply.

- A proper recovery technique is still required.

The tradeoff is speed. Using more winch line means recoveries take longer, but the slower pace reduces shock loading and improves safety. This is why mechanical advantage is a foundational principle in system-based winch recovery, not just an optional technique.

Mechanical advantage explains why winch capacity alone doesn’t determine recovery success. In high-resistance situations, how the force is managed matters more than how much force is available.

Because this approach prioritizes strain reduction over brute force, differences become more noticeable between winches that perform best under real recovery loads, where smooth operation and durability matter more than headline ratings.

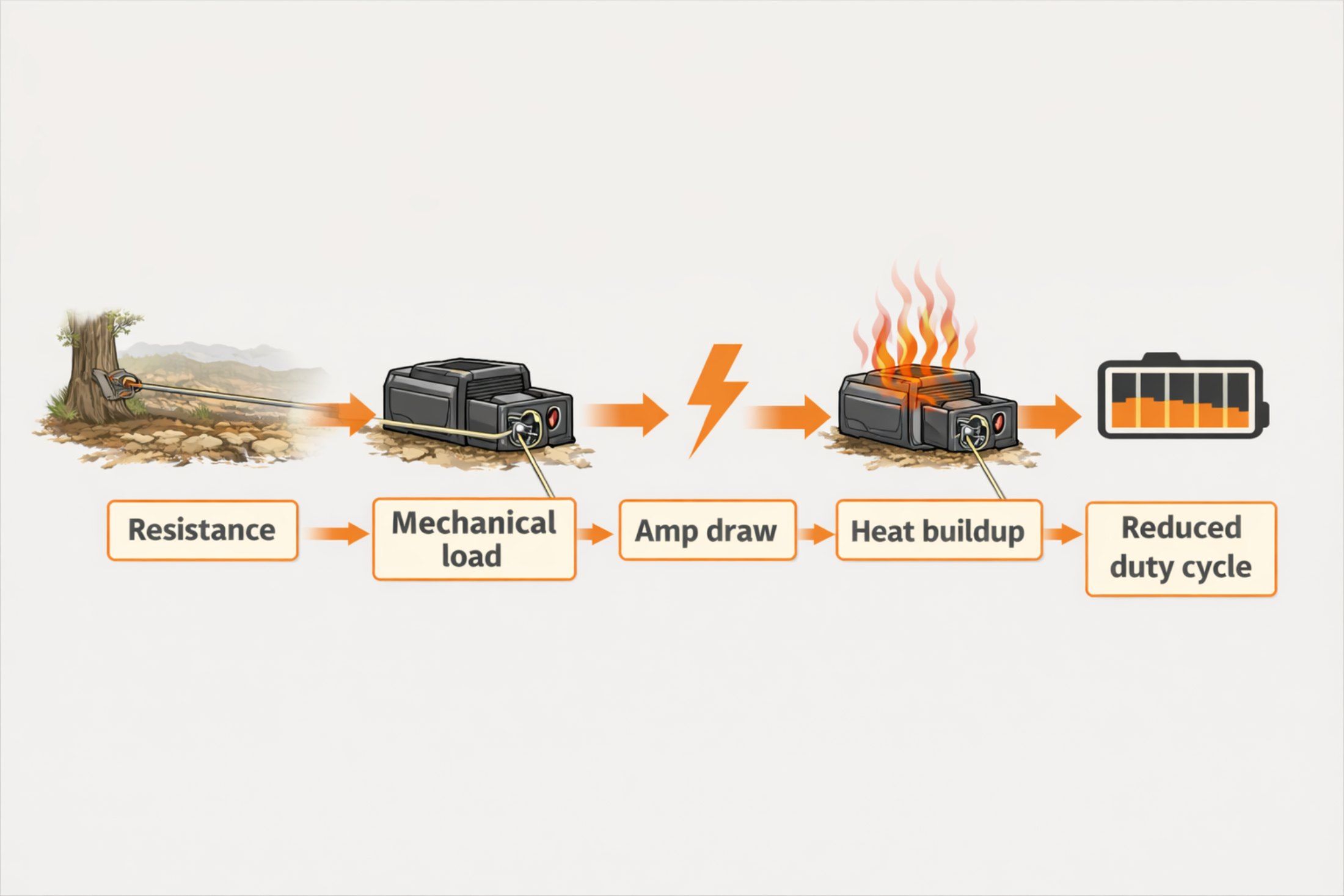

How Snatch Blocks Reduce Winch Load and Electrical Strain

Snatch blocks reduce winch load and electrical strain by lowering the force the winch motor must generate, which directly decreases amp draw, heat buildup, and voltage drop during recovery.

Electric winches fail more often from electrical overload than from lack of pulling power. As resistance increases, the winch motor draws more current, stressing the battery, stator, wiring, and solenoid. A snatch block interrupts this cycle by reducing the load the motor must overcome, allowing the winch to operate within a safer electrical range during sustained pulls.

What ultimately limits most winch recoveries isn’t pulling power but how long the electrical system can sustain load without overheating, a constraint explored in more detail when discussing winch duty cycle and overheating limits.

When mechanical load is reduced, electrical demand drops proportionally. This lowers heat buildup in the motor and wiring, improves voltage stability, and allows the winch to maintain output longer without stalling or requiring cooldown periods. For UTVs with limited electrical capacity, this reduction often determines whether a recovery remains controlled or becomes intermittent.

When You Should Use a Snatch Block During UTV Recovery

A snatch block should be used during UTV recovery when resistance, duration, or terrain conditions would otherwise overload the winch or electrical system during a direct pull.

A snatch block is not needed for every recovery. Its value increases as resistance becomes less predictable or more sustained. The goal is to reduce stress before the winch nears its mechanical or electrical limits.

Situations Where a Snatch Block Is Recommended

Deep mud or suction-heavy terrain: Mud creates resistance far greater than vehicle weight. As suction breaks, load spikes can occur suddenly. A snatch block reduces peak stress on the winch during these transitions.

Steep inclines or uphill recoveries: Gravity adds continuous resistance. Mechanical advantage helps prevent winch stall and excessive heat buildup during long pulls.

Heavily loaded or accessorized UTVs: Cargo, tools, plows, and passengers increase rolling resistance and recovery demand beyond dry vehicle weight.

Extended or low-speed recoveries: Long pulls amplify electrical strain over time. Reducing load allows the winch to operate within a safer duty cycle.

In these scenarios, a snatch block lets the winch function as part of a controlled recovery system, rather than operating at maximum output continuously.

Experienced recovery operators often use a snatch block as a preventive measure, applying it before the winch is overstressed, not after performance declines.

When a Snatch Block Is NOT Necessary (or Can Be Misused)

A snatch block is unnecessary when recovery resistance is low and predictable, and it can be misused if added without proper anchoring, load ratings, or recovery technique.

While snatch blocks improve safety in high-resistance recoveries, unnecessary use can complicate setup and introduce avoidable risks. Effective recovery depends on selecting the right level of system complexity for each situation.

Situations Where a Snatch Block Is Often Unnecessary

Short, straight pulls on firm ground: When traction loss is minimal and resistance is consistent, a direct pull is typically sufficient.

Lightly stuck vehicles: If the UTV can move with minimal winch input, adding a pulley offers little benefit and slows recovery.

Time-sensitive recoveries: In low-risk situations where speed matters more than load reduction, a simple pull may be more appropriate.

Common Snatch Block Misuse Scenarios

Using a snatch block without a solid anchor: Mechanical advantage increases system forces. Weak anchors can fail even when the winch is lightly loaded.

Substituting hardware for technique: Snatch blocks cannot compensate for poor line angles, improper anchoring, or unsafe positioning.

Ignoring component load ratings: Underrated pulleys, shackles, or straps may fail before the winch reaches its limit.

In low-resistance recoveries, adding unnecessary hardware increases setup time and the risk of routing or anchoring errors. Good recovery practice emphasizes selecting appropriate tools, not using the maximum amount of hardware.

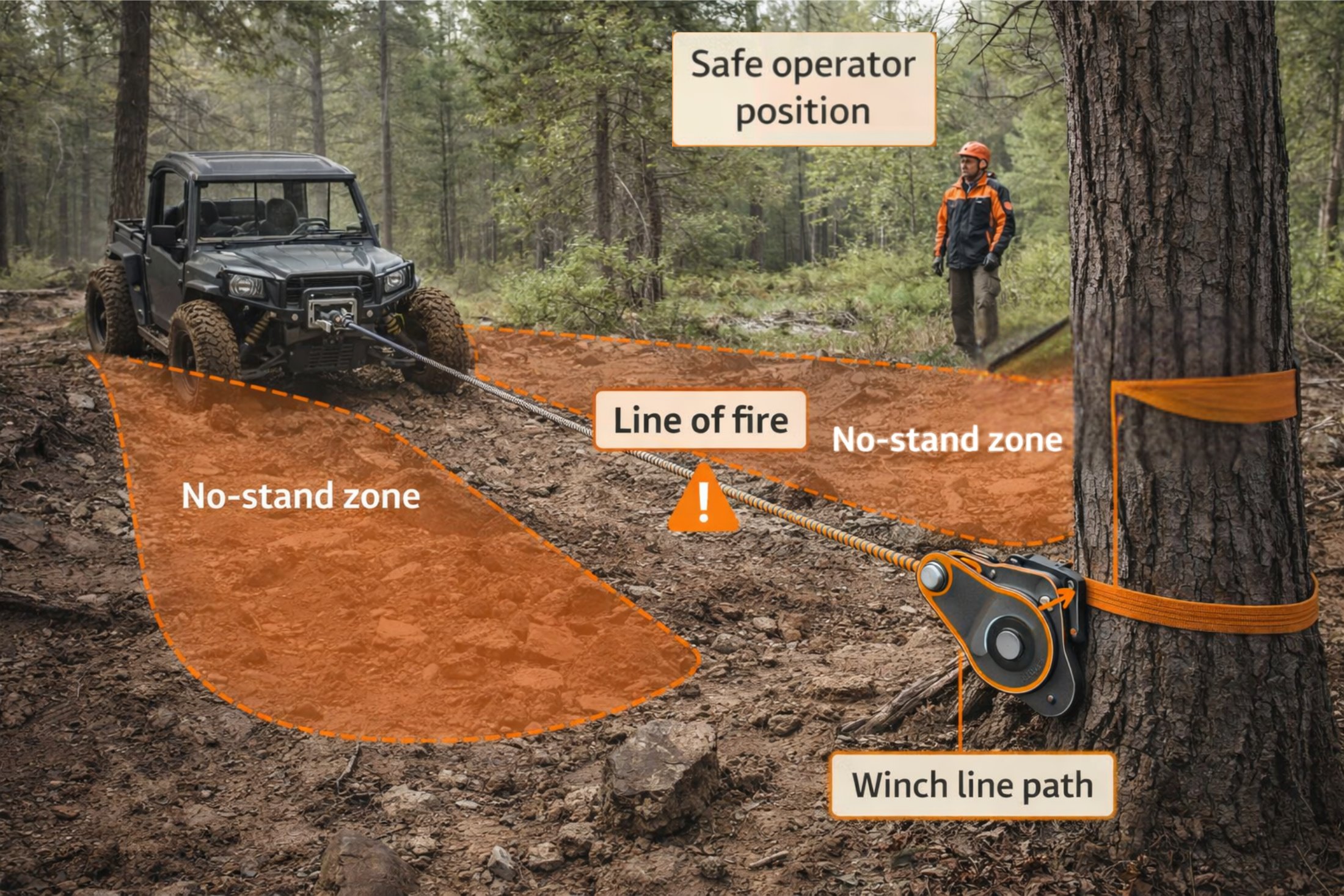

Snatch Block Safety Rules Every UTV Owner Should Follow

Snatch block safety rules exist to manage stored energy, control load paths, and reduce injury risk during winch-assisted UTV recovery.

Most winching injuries don’t occur because equipment breaks, but because force is redirected without accounting for failure paths, a pattern commonly seen in real-world winching safety failures.

Winching systems store significant energy under load. A snatch block increases system complexity and redistributes forces, making disciplined safety practices essential.

Core Snatch Block Safety Principles

Use only load-rated hardware: The snatch block, shackles, straps, and anchor points must be rated above the expected recovery load. Underrated components often fail before the winch does.

Protect and stabilize anchor points: Always use a tree saver strap or rated anchor to prevent slippage, bark damage, or anchor failure under tension.

Stay out of the line of fire: No one should stand near the winch line, snatch block, or anchor while the system is under load. If a component fails, stored energy is released instantly.

Use a winch line damper: Even synthetic rope stores energy when tensioned. A damper reduces recoil force if the line or hardware fails.

Inspect before every pull: Check for cracked side plates, seized pulleys, damaged rope fibers, or bent shackles. Small defects become failure points under load.

These rules focus on controlling energy release, not just preventing equipment wear. Most recovery injuries occur when safety zones and load paths are ignored.

Following consistent safety procedures allows snatch blocks to improve recovery outcomes without increasing risk, especially when used as part of a complete winch recovery system.

Common Snatch Block Mistakes That Cause Equipment Failure

Snatch block failures are most often caused by system-level mistakes, such as underrating, poor anchoring, and excessive heat buildup, rather than defects in the pulley itself.

Most recovery failures occur when components are pushed beyond their design limits due to incorrect setup or sustained overload. Snatch blocks amplify both good and bad recovery practices.

Frequent Mistakes to Avoid

Using an underrated or unknown snatch block: If the pulley or side plates are not rated for the recovery load, deformation or fracture can occur even when the winch is operating normally.

Anchoring to unstable or weak objects: A mechanical advantage increases the forces at anchor points. Trees, bumpers, or improvised anchors can fail suddenly under redirected load.

Running the winch at maximum load continuously: Extended high-load operation generates heat in the motor, wiring, and rope. Heat buildup accelerates wear and leads to a stall or electrical failure.

Allowing the winch line to contact the pulley side plates: Misalignment causes friction, heat, and rope damage. This reduces efficiency and compromises rope strength over time.

Each of these mistakes increases friction, shock loading, or thermal stress in the recovery system. Addressing them requires system awareness, not just stronger hardware.

Understanding these failure modes reinforces the need to use snatch blocks as part of a controlled recovery setup, not as a last-minute solution when a pull becomes difficult.

Snatch Block or Bigger Winch: Which Truly Enhances Your UTV Recovery?

When your UTV is stuck in deep mud, the key factor is not whether you have a 3,500 lb or 4,500 lb winch, but how well you are prepared for recovery. A snatch block is effective with either winch, providing a practical way to manage the load and safely recover your vehicle.

While a 4,500 lb winch has greater pulling capacity than a 3,500 lb model, both can be pushed beyond safe limits by factors such as deep mud, steep inclines, increased vehicle weight, or prolonged use. For example, knee-deep mud can increase rolling resistance to 9,000 lb, risking overload for either winch. In these cases, effective load management is more important than winch rating alone.

A higher-rated winch does not reduce resistance; it only withstands more before stalling or overheating. A 4,500 lb winch may still struggle in challenging terrain if the recovery relies solely on a direct, continuous pull.

If ratings alone don’t tell the full story, choosing a winch that performs reliably under real recovery loads becomes the next decision, which is where a breakdown of the best UTV winches for 2026 helps put these tradeoffs into context.

The key consideration is whether your recovery setup keeps the winch within safe operating limits. When resistance is high or unpredictable, using a snatch block often enhances reliability more than upgrading to a larger winch. This approach reduces strain, improves control, and minimizes the need for frequent cooldowns.

In UTV recovery, winch rating sets the maximum capacity, but technique determines actual performance. Using a snatch block is a straightforward way to stay within safe limits when conditions become challenging.

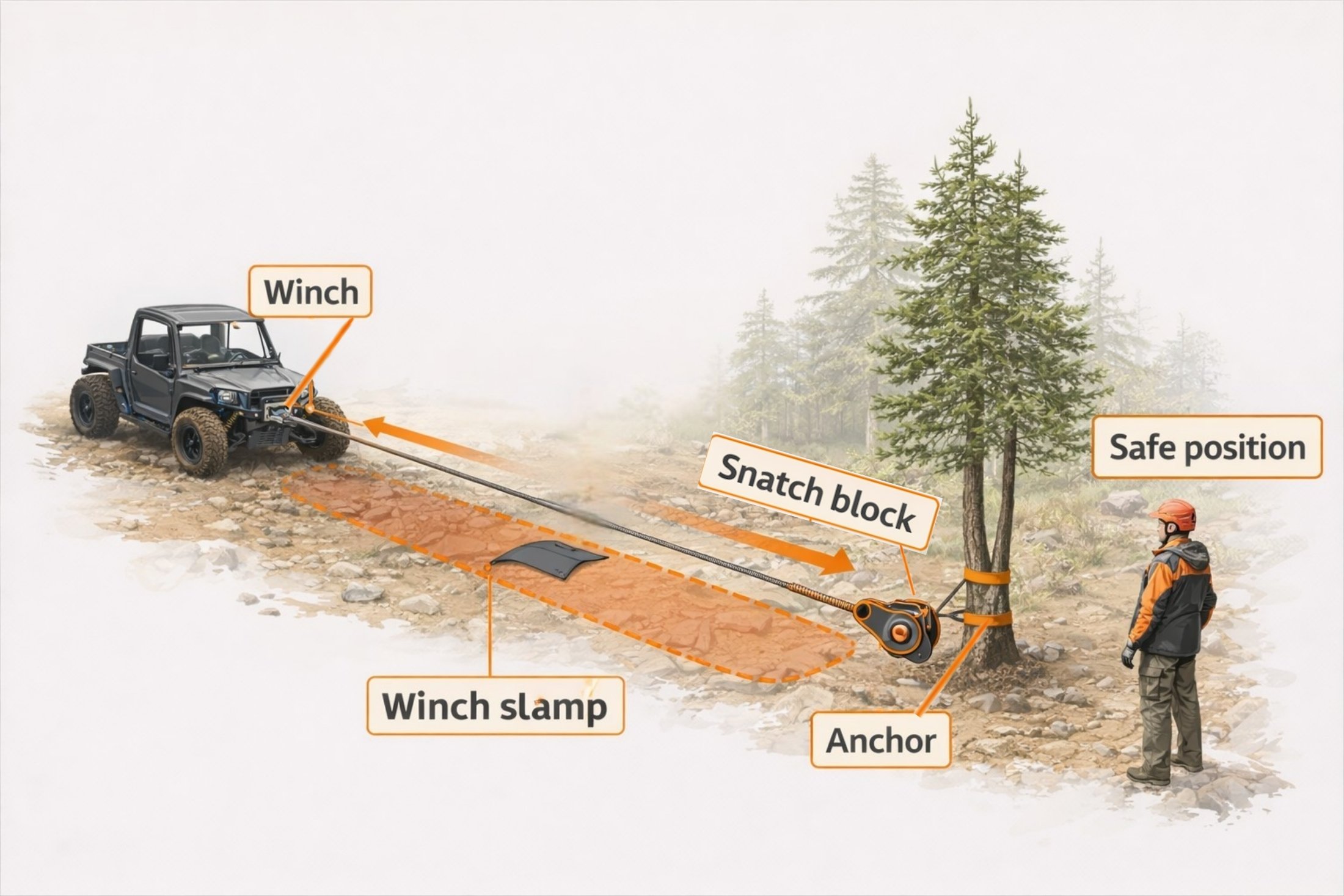

Snatch Blocks as Part of a Complete Winch Recovery System

A snatch block is one component of a complete winch recovery system that manages force, electrical load, and control through coordinated use of rated equipment and proper technique.

Snatch blocks are most effective when integrated into a recovery system, not used as isolated hardware. Safe winching depends on how all components interact under load, not on the strength of any single part.

Elements of a Proper UTV Winch Recovery System

Correctly sized winch

The winch must match the vehicle’s weight class and intended use, but should not be used at maximum capacity for difficult recoveries.

Winch line suited to recovery conditions

Synthetic rope or properly maintained cable must be compatible with pulley size and routing to reduce friction and wear.

Rated snatch block and anchor equipment

Pulleys, shackles, straps, and anchor points must be rated to withstand the redirected forces from mechanical advantage.

Controlled recovery technique

Line alignment, gradual tensioning, and safe positioning determine how effectively the system manages load and stored energy.

When these elements work together, recoveries become more predictable and less stressful foripment and electrical systems. This system-based approach reduces failure risk and improves safety in complex terrain.

Treating snatch blocks as part of an integrated recovery system, not as an afterthought, reinforces the importance of technique and setup alongside winch capacity.

Frequently Asked Questions About Snatch Blocks

What does a snatch block do for a winch?

A snatch block increases mechanical advantage, reducing load on the winch and lowering electrical strain, heat buildup, and the risk of winch failure during recovery.

By redistributing force via an additional winch line, the winch motor experiences less stress while still moving the vehicle.

Does a snatch block double winch pulling power?

No. A snatch block does not double the pulling power; it reduces the load seen by the winch, slowing the pull and requiring more line.

The vehicle still experiences the same resistance from weight, terrain, and suction. The benefit is improved control and reduced strain on the winch system.

Can a snatch block damage a winch?

Yes, if it is underrated, improperly anchored, or used with a poor recovery technique.

When correctly rated and used as part of a controlled recovery setup, a snatch block protects the winch by lowering load and electrical demand rather than increasing risk.

Is a snatch block necessary for UTV winching?

A snatch block is not always necessary, but it is strongly recommended in deep mud, steep terrain, or long recoveries where resistance exceeds what a direct pull can safely sustain.

In low-resistance situations, a direct pull is often sufficient.

When should I choose a snatch block over a larger winch?

A snatch block is often the better solution when electrical limits—not rated pulling capacity—are the primary constraint.

Reducing load with mechanical advantage frequently improves reliability more than upgrading to a higher-capacity winch, especially on UTVs with limited electrical output.

Final Takeaway

A snatch block improves UTV winch recovery by reducing strain and increasing control as resistance builds, especially in mud, on steep terrain, or during long pulls.

The point isn’t pulling harder. It’s keeping the winch out of situations where heat, electrical load, and sustained resistance compound and lead to failure. Mechanical advantage gives the system breathing room, which is often what determines whether a recovery stays controlled or turns into a stop-and-wait process.

In practice, recovery success has less to do with headline winch ratings and more to do with how force is managed once the pull begins. A snatch block doesn’t replace good judgment or proper setup, but it consistently extends both. Used deliberately, it shifts winching from a high-stress effort into a manageable, repeatable process.

Continue Exploring Related Topics:

- Balancing winch performance and cost

- How ATV and UTV winches differ in recovery use

- How winch manufacturers approach durability

ATVNotes is an off-road resource focused on ATV and UTV winching, recovery systems, safety gear, tires, batteries, and essential off-road equipment. Content is produced by the ATVNotes Expert Team and written from the perspective of a practical off-road recovery advisor, emphasizing real-world performance, system compatibility, and safety-first practices across trail riding, utility use, and off-road exploration.