Most UTV winch failures are caused by overheating, not by insufficient pulling power.

Heat builds inside the winch motor and electrical components when the winch operates under load for too long. As temperatures rise, performance drops, even if the winch is rated well above the vehicle’s weight.

In the field, this often happens during routine recoveries rather than extreme situations.

The operating limit that controls this behavior is called the winch duty cycle.

This explains why a winch can perform flawlessly during multiple recoveries, only to suddenly overheat under similar conditions. Recovery resistance, electrical capacity, and operator technique govern how quickly heat builds, making heat management—not pull rating—the limiting factor in real-world use.

Jump To Contents

- What Is UTV Winch Duty Cycle?

- How Long Can a UTV Winch Pull Before Overheating?

- Why UTV Winches Overheat During Recovery

- Duty Cycle vs Winch Strength — Why Bigger Isn’t Always Safer

- Electrical Constraints That Accelerate Winch Overheating

- How Snatch Blocks Reduce Heat and Extend Duty Cycle

- Budget vs Premium UTV Winches — Duty Cycle Differences That Affect Reliability

- Signs Your UTV Winch Is Overheating

- How Recovery Technique Affects Winch Duty Cycle

- Best Practices to Prevent UTV Winch Overheating

- FAQs on Winch Duty Cycle – Quick Answers

- How can I tell if my winching technique is causing overheating?

- Why does my winch stop and then work again later?

- Is winch overheating more common on UTVs than on trucks?

- Is overheating more likely during mud recoveries?

- Will upgrading my battery prevent the winch from overheating?

- What’s the safest way to extend the duty cycle without upgrading equipment?

- Can improper technique permanently damage a winch?

- Final Takeaway: Duty Cycle Matters More Than Advertised Pull Rating

What Is UTV Winch Duty Cycle?

UTV winch duty cycle is the maximum amount of time an electric winch can operate under load before heat buildup requires a cooling period to prevent damage.

Simple definition. But here’s where most people get tripped up.

It’s about how quickly heat builds up inside the motor and solenoid while you’re pulling.

That’s why a winch can feel unstoppable for 20 seconds—and then suddenly slow to a crawl.

Most DC electric UTV winches can briefly deliver high torque. Sustaining that torque is the problem. As current draw increases, internal temperatures rise rapidly.

In practice, duty cycle answers a very specific question:

How long can you pull before heat becomes the limiting factor?

Duty cycle is often expressed as a percentage over a set time period, usually ten minutes. For example, a 10% duty cycle typically means about 1 minute of loaded pulling followed by about 9 minutes of cooling.

Many manufacturers don’t publish duty cycle ratings at all. That’s why real-world reliability depends less on spec sheets and more on operator judgment during recovery.

How Long Can a UTV Winch Pull Before Overheating?

Most UTV winches are built for short, controlled recovery pulls—not continuous operation.

That’s an important distinction.

Under heavy recovery loads, many UTV winches can operate for only a minute before heat buildup becomes a concern. Push past that, and you’re no longer testing pulling power—you’re testing thermal limits.

In real-world recoveries, the difference is obvious.

Light loads and short pulls often allow repeated winching with little heat buildup. But deep mud, snow, or uphill recoveries can push a winch toward overheating in under 60 seconds. Near-stalled pulls are even worse. That’s when heat builds fastest.

What most riders miss is how quickly heat accumulates once resistance increases, even when the winch still feels strong.

If you’ve ever wondered why a winch overheated on one recovery but handled several others just fine, this is why. Time alone doesn’t tell the full story.

Why Time Alone Is Misleading

Time is a poor predictor of winch overheating.

Load is what matters.

As resistance increases, motor current rises sharply. Voltage drops across the electrical system. The excess energy doesn’t disappear—it turns into heat.

One recovery moves smoothly with minimal strain. Another, under higher resistance, overheats almost immediately. Same winch. Same vehicle. Very different thermal outcome.

When the voltage drops, the motor compensates by drawing more current. That current accelerates heat buildup inside the windings and solenoid.

This is why overheating often shows up as a slowing of line speed or a delayed response, long before the winch fully stalls.

Why UTV Winches Overheat During Recovery

Winch overheating is not caused by a single failure point. It results from a cumulative chain of cause and effect, driven by the physical and electrical limitations typical of side-by-side vehicles.

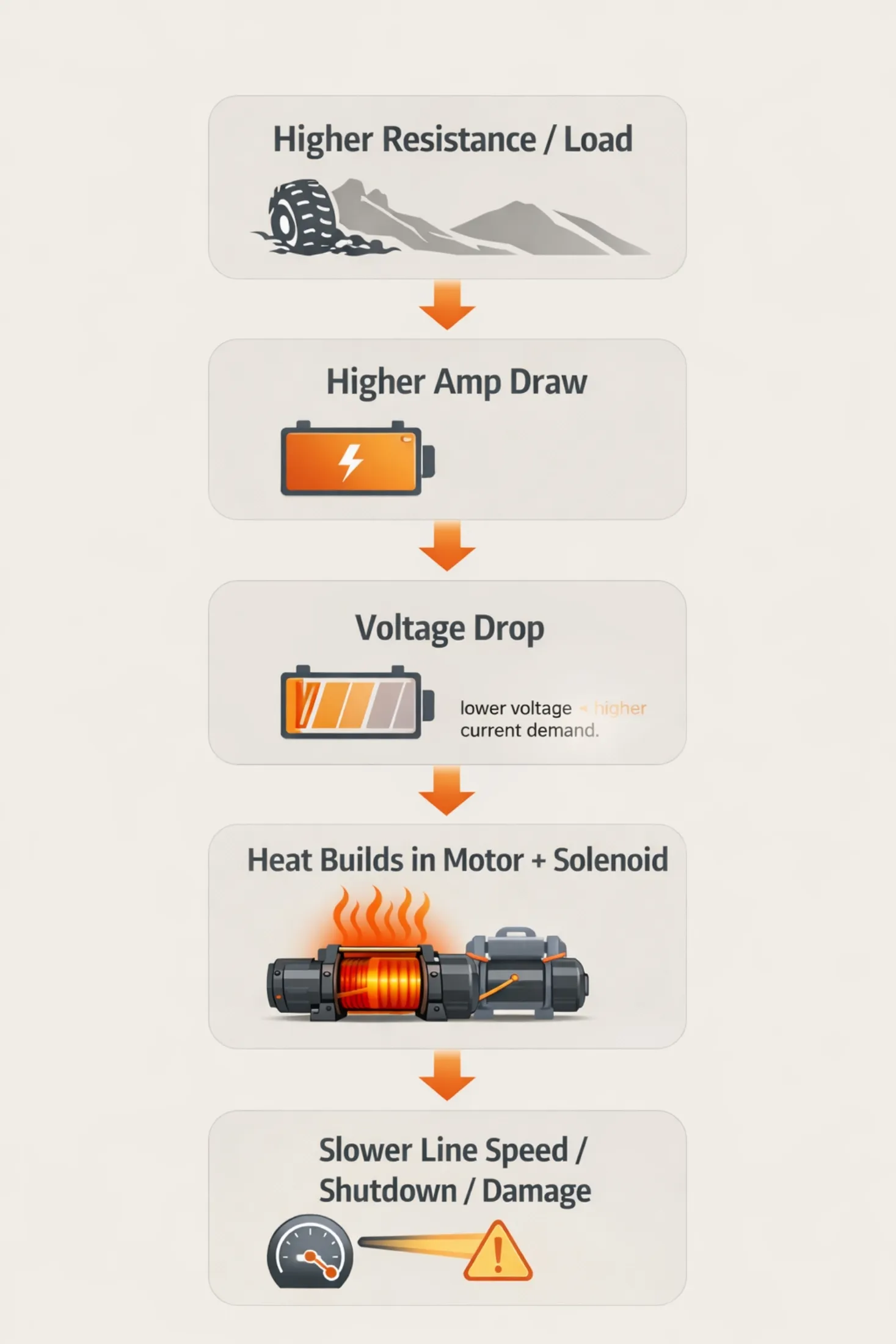

The Winch Overheating Chain – Cause → Effect

1. High recovery load

Mud suction, incline resistance, and vehicle weight increase the force required to move the UTV.

⬇

2. Increased amp draw

As resistance rises, the series-wound electric motor draws more current to maintain torque.

⬇

3. Voltage drop

Small UTV batteries and low-output stators struggle to maintain voltage under sustained load.

⬇

4. Heat generation

Electrical resistance converts excess current into heat inside the motor windings and solenoid (contactor pack).

⬇

5. Thermal overload

Internal temperatures exceed safe limits, slowing the winch, triggering shutdowns, or causing permanent damage.

Series-wound DC motors make this worse. They’re excellent at producing torque at low speed, but they heat up quickly under sustained load. That design works well for short pulls. It’s unforgiving during continuous winching.

Add in small batteries, low-output stators, and long wiring runs, and the thermal margin disappears fast.

Factor → Effect Summary Table

| Factor | Effect on Duty Cycle |

| High recovery resistance | Increases amp draw and heat |

| Voltage drop | Forces the motor to work harder |

| Series-wound motor design | Produces torque but heats quickly |

| Snatch block use | Reduces load and thermal stress |

Many duty-cycle failures occur when ATV-rated winches are used on heavier UTV platforms, where sustained loads exceed their thermal design limits. If you’ve ever wondered why a winch rated for your vehicle still struggles, the differences between ATV and UTV winches explain it clearly.

Duty Cycle vs Winch Strength — Why Bigger Isn’t Always Safer

Winch strength and duty cycle are often confused. They’re not the same thing.

Pull rating indicates how much force a winch can exert. Duty cycle tells you how long that force can be applied before heat becomes a problem.

A winch can be strong enough to move the vehicle and still overheat before the recovery is finished.

That’s why higher-capacity winches don’t automatically mean safer recoveries. They may pull harder on the first layer of rope and stall less easily at the start—but sustained load still generates heat.

In real use, some lower-rated winches feel more reliable simply because they’re operated within their thermal limits. Meanwhile, more powerful units fail early when pushed continuously.

Strength determines what a winch can move.

Duty cycle determines whether it can finish the job.

Electrical Constraints That Accelerate Winch Overheating

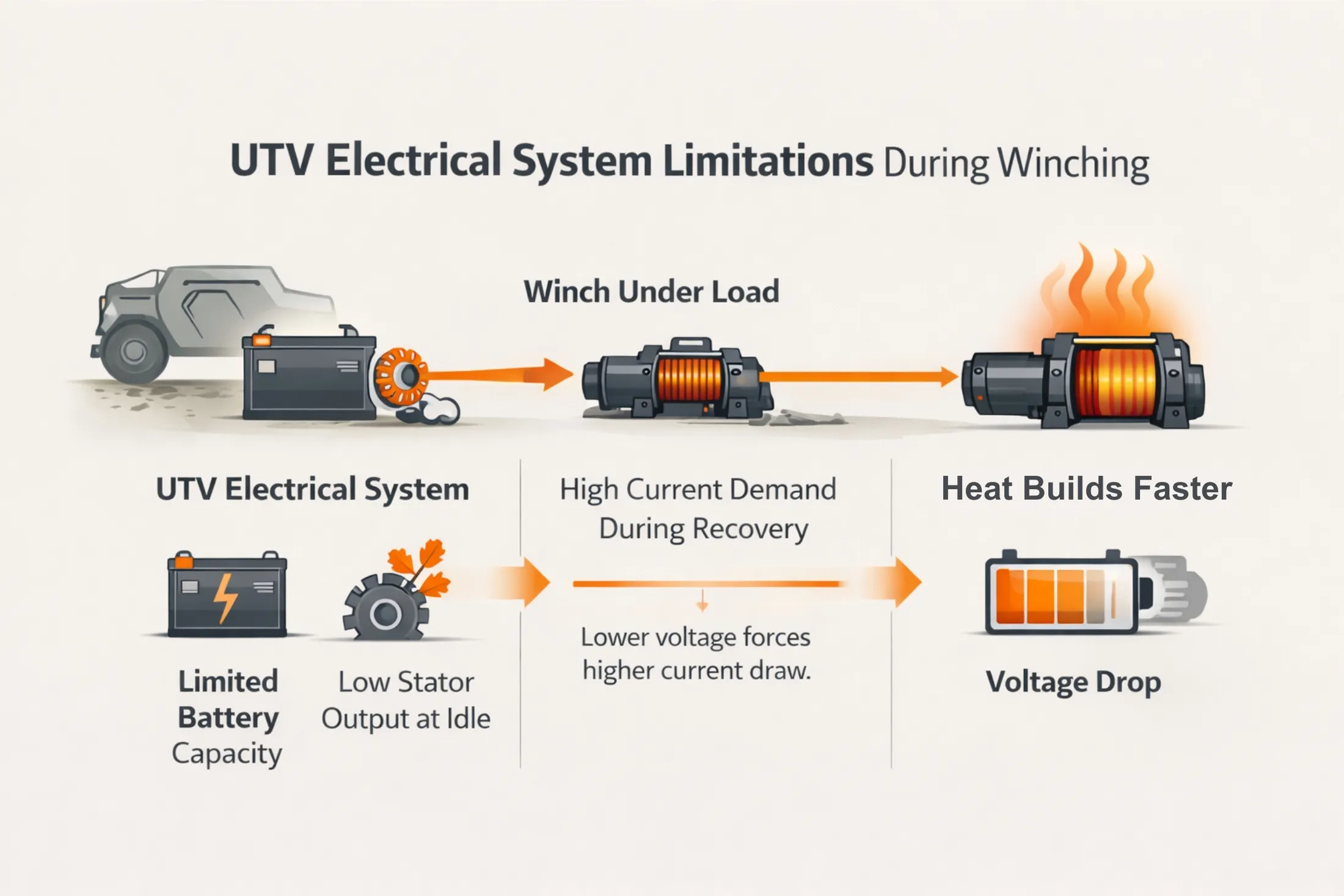

Electrical limitations common to UTVs—particularly voltage instability under load—often become the primary factor that accelerates heat buildup and shortens usable winch duty cycle during recovery.

Voltage Drop Is the Primary Limiting Factor

As already said, UTV winch overheating is strongly influenced by electrical system limitations that reduce available voltage under load. When the voltage drops, the winch motor compensates by drawing more current, which accelerates heat buildup inside the motor and solenoid.

The limiting factor is voltage stability, not advertised strength.

Why UTV Electrical Systems Struggle Under Load

Most UTVs operate with compact electrical systems that offer little reserve capacity during winching. Battery size is limited, stator output is low at idle or slow trail speeds, and charging systems are not designed to support sustained high current draw.

As a result, voltage begins to fall soon after winching starts, especially during heavy or prolonged recoveries.

What Happens as Voltage Continues to Fall

In practical recoveries, this effect is easy to observe. A winch may begin pulling normally, then gradually slow as battery voltage decreases. That additional current converts directly into heat, even if the recovery load remains constant.

This is why line speed often drops before a winch stalls or shuts down.

Repeated Pulls Increase Thermal Stress

Electrical constraints become more pronounced during repeated recoveries. Between pulls, the stator often cannot restore battery charge quickly enough. Each new recovery begins at a lower voltage than the previous one.

As voltage starts lower, heat builds faster, shortening the usable duty cycle with each pull.

Wiring and Connections Amplify Voltage Loss

Wiring quality plays a significant role in voltage behavior. Long cable runs, undersized wiring, corroded terminals, and loose connections all increase electrical resistance.

Even small voltage losses at the battery or solenoid can significantly increase current draw at the winch motor under load, accelerating heat buildup during recovery.

Why Electrical Limits Define Usable Duty Cycle

Electrical constraints do not reduce a winch’s rated pulling capacity. They determine how long the winch can operate before heat becomes the limiting factor.

In UTV applications, voltage stability often defines usable duty cycle more than pull rating alone. So, winch accessories that reduce resistance and voltage loss help preserve usable duty cycle, particularly during repeated or high-load recoveries.

How Snatch Blocks Reduce Heat and Extend Duty Cycle

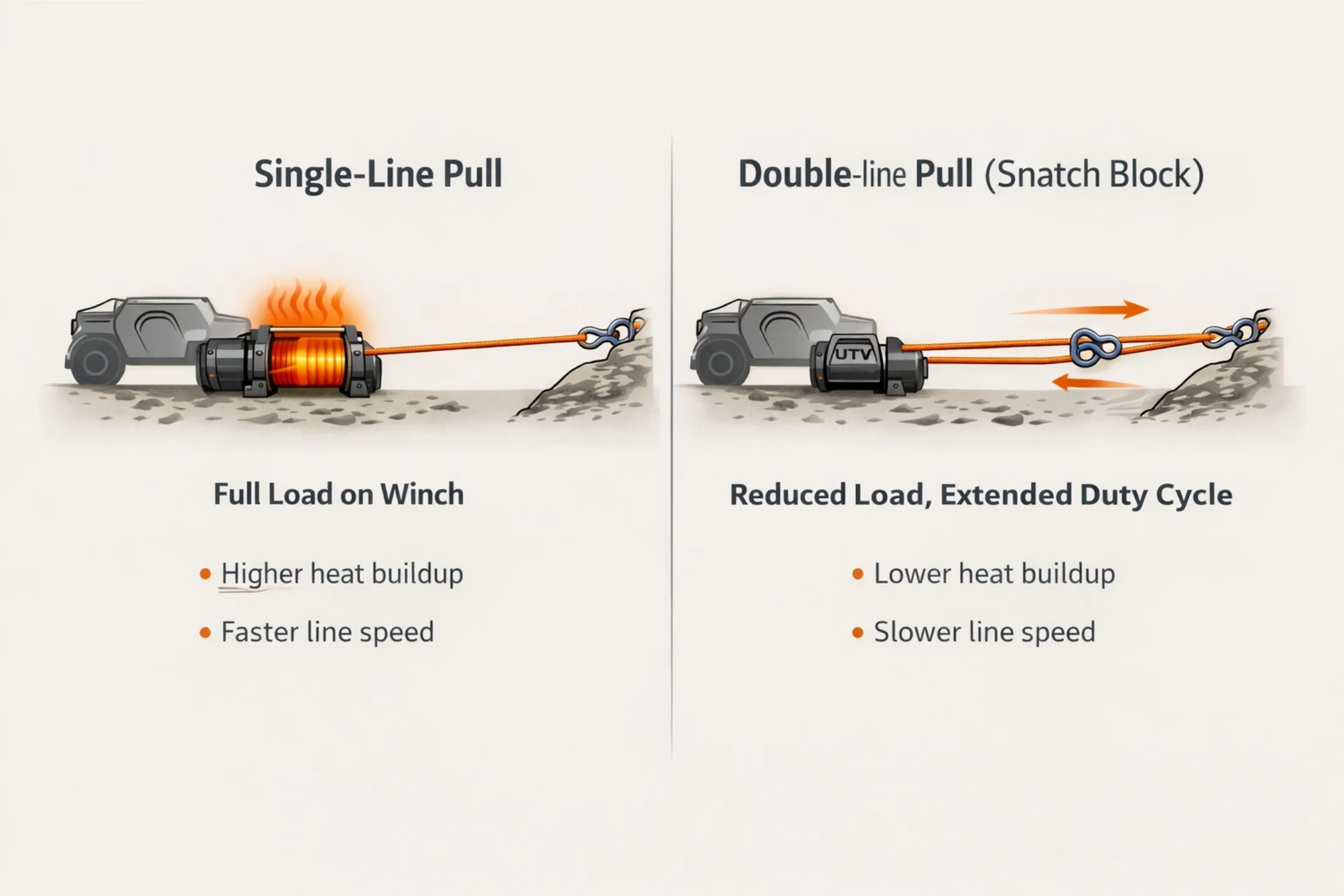

A snatch block extends a UTV winch’s duty cycle by reducing the load on the winch motor, lowering current draw, and slowing heat accumulation during recovery.

A snatch block does not increase a winch’s strength. Instead, it changes the mechanics of the pull so the winch can operate within safer thermal limits.

Dig deeper: How Snatch Blocks Work for UTV Winching

How Mechanical Advantage Reduces Heat

When a snatch block is used in a double-line configuration, the winch line is routed through the block and back to the vehicle or anchor point. This setup divides the recovery load across two line segments, meaning the winch motor only has to generate roughly half the torque required for a single-line pull.

With lower torque demand, the motor draws less electrical current. Reduced current lowers internal resistance losses, thereby slowing heat buildup in the motor windings and solenoid.

Riders usually notice the difference immediately — slower line speed, but a winch that keeps pulling instead of fading under load.

Why This Extends Duty Cycle

Lower motor load leads to:

- Reduced amp draw

- Slower voltage drop

- Less heat is generated per second of operation

As a result, the winch can operate longer before reaching its thermal limit, allowing difficult recoveries to be completed without forcing shutdowns or risking permanent damage.

The Trade-Off: Line Speed vs Reliability

Using a snatch block roughly halves line speed. However, the reduction in speed is offset by improved control, reduced electrical stress, and significantly increased recovery reliability.

In real recovery situations—especially deep mud, steep inclines, or near-stalled pulls—the ability to maintain steady movement matters far more than raw line speed.

Budget vs Premium UTV Winches — Duty Cycle Differences That Affect Reliability

When comparing budget and premium UTV winches, the most important difference is not pull rating. Pointed out several times by now, it is the duty-cycle performance in real recovery situations.

Many UTV winches advertise similar pulling capacities, but they do not perform the same under sustained load. In practice, the deciding factor is how well the winch manages heat during repeated or difficult recoveries. This is where price differences become meaningful.

Explore: Best UTV Winches for Occasional Recovery (2026)

Budget UTV Winches: Best for Occasional Recovery Use

Budget UTV winches are designed for riders who need a recovery tool occasionally rather than frequently. They can offer good value when matched correctly to vehicle weight and used properly.

Typical characteristics of budget winches include:

- Shorter duty cycles during heavy or repeated pulls

- Faster heat buildup when recovering from mud, snow, or steep terrain

- Greater sensitivity to battery condition and voltage drop

- Strong reliance on cooling pauses and load-reduction techniques

For riders who winch infrequently, a budget UTV winch can be a practical and cost-effective choice. Problems usually arise when these winches are used continuously or beyond their intended recovery profile.

Premium UTV Winches: Built for Repeated and Demanding Recoveries

Premium UTV winches are designed for riders who expect frequent recoveries or operate in consistently challenging terrain. The higher cost reflects improved thermal management rather than raw pulling power.

Common characteristics of premium winches include:

- Longer usable duty cycles under sustained load

- More consistent line speed during repeated recoveries

- Improved motor efficiency and heat resistance

- Better tolerance of voltage fluctuations in UTV electrical systems

These advantages reduce the likelihood of overheating during long or complex recoveries, which is why premium winches are often preferred for heavier UTVs, trail riding, work applications, and recovery-heavy environments.

What Paying More for a UTV Winch Actually Gets You

A higher-priced UTV winch does not remove thermal limits. It increases thermal margin.

Premium winches typically use higher-quality motor windings, improved internal tolerances, and more durable contactors or solenoids. These components reduce electrical losses, which slows heat accumulation under load and extends the effective duty cycle.

The result is a winch that maintains performance longer before requiring cooling pauses. Expert opinions put in the UTV winch recommendations, can provide sharper insight into this debate.

Signs Your UTV Winch Is Overheating

A UTV winch can overheat before fully stalling or shutting down. Recognizing early warning signs helps prevent permanent motor or electrical damage.

- Slower line speed: A noticeable reduction in line speed indicates rising internal resistance and increasing heat inside the motor.

- Delayed or intermittent response: Hesitation when pressing the remote often signals heat-affected electrical flow through the solenoid or wiring.

- Clicking without drum movement: The solenoid may engage while the motor is thermally stressed or experiencing a severe voltage drop.

- Hot electrical smell: A burning or sharp electrical odor suggests overheating insulation, wiring, or solenoid contacts.

- Automatic shutdown or thermal cut-out: Some winches include basic thermal protection that temporarily disables operation when internal temperatures exceed safe limits.

- The winch works again after cooling: Temporary recovery after a cooling period is a strong indicator of thermal overload rather than mechanical failure.

In many cases, these warning signs appear well before permanent damage occurs, but they are often ignored during recovery.

How Recovery Technique Affects Winch Duty Cycle

Recognizing the symptoms of an overheating winch identifies when thermal limits are being reached. The recovery technique determines how quickly those limits are exceeded during operation.

Continuous Pulling Increases Heat Accumulation

Sustained winching keeps the electrical current high with little opportunity for internal heat to dissipate. Even when the winch is moving the vehicle, continuous pulling accelerates the temperature rise inside the motor and solenoid.

In real recoveries, this often happens when operators try to “power through” resistance instead of managing load and cooling time.

Stalling the Winch Generates the Most Heat

Near-stalled or fully stalled pulls place the highest thermal stress on a winch. When the drum stops moving, but electrical input continues, the current draw spikes while little work is being done.

This condition produces heat faster than any other operating state and can cause rapid thermal overload, even during short recovery attempts.

Stop-and-Go Pulling Reduces Thermal Stress

Short, controlled pulls with brief pauses allow internal components to shed heat between cycles. Even small pauses can significantly reduce cumulative thermal stress during difficult recoveries.

This technique extends usable duty cycle without changing equipment or increasing pull rating.

Load Reduction Improves Thermal Efficiency

Reducing resistance before winching lowers the torque demand placed on the motor. Clearing obstacles, adjusting pull angles, repositioning the vehicle, or using a snatch block all decrease current draw and slow heat buildup.

In the field, load reduction often has a greater impact on winch temperature than winch size alone.

Operator Awareness Prevents Cumulative Overheating

Paying attention to line speed, sound, and response time helps operators recognize rising thermal stress early. Slowing line speed or delayed response often indicates increasing internal temperatures.

Adjusting the technique at these early signs, as covered in depth earlier, prevents cumulative overheating and extends winch life.

Why Technique Often Matters More Than Winch Size

Proper technique allows even modest winches to complete difficult recoveries, while poor technique can overheat high-capacity winches in minutes.

In real-world UTV use, operator decisions often define usable duty cycle more than pull rating alone.

Many overheating incidents stem from avoidable recovery errors that compound thermal stress and increase the risk of electrical or mechanical failure during winching.

Best Practices to Prevent UTV Winch Overheating

UTV winch overheating is best prevented by limiting continuous load, reducing resistance, and allowing heat to dissipate between pulls.

Since most UTV winches lack advanced thermal protection, the operator serves as the primary safeguard against heat damage.

Winch Overheating Prevention Checklist

- Use short, controlled pulls

→ Limits sustained current draw and heat buildup

- Pause between heavy pulls

→ Allows internal motor and solenoid temperatures to drop

- Reduce the load before winching.

→ Reposition the vehicle, clear obstacles, or change angles

- Use a snatch block when resistance is significant.

→ Cuts motor load and slows heat accumulation

- Monitor line speed and tension.

→ Sudden slowing indicates rising thermal stress

- Maintain electrical health

→ Clean terminals and healthy batteries reduce voltage loss

Most winch failures can be prevented through effective heat management rather than simply upgrading winch size.

FAQs on Winch Duty Cycle – Quick Answers

These answers address common duty-cycle questions with symptom- and cause-based explanations suitable for People Also Ask and AI summaries.

How can I tell if my winching technique is causing overheating?

If the winch slows down, clicks without pulling, or requires frequent cooling pauses, technique-related heat buildup is occurring. These signs indicate excessive load duration rather than insufficient pulling power.

Why does my winch stop and then work again later?

This usually indicates thermal or voltage stress. After cooling or voltage recovery, the winch may function again—but repeated overheating shortens its lifespan.

Is winch overheating more common on UTVs than on trucks?

Yes. UTVs have smaller batteries, lower-output stators, and lighter wiring, which cause voltage drop and heat buildup to occur faster under load.

Is overheating more likely during mud recoveries?

Yes. Mud creates suction and rolling resistance, increasing load, raising amp draw, and accelerating heat buildup.

Will upgrading my battery prevent the winch from overheating?

A higher-capacity battery can delay voltage drop, but cannot eliminate heat buildup. Proper technique and load reduction remain essential.

What’s the safest way to extend the duty cycle without upgrading equipment?

Use short pulls, cooling pauses, snatch blocks, and monitor line speed instead of forcing tension.

Can improper technique permanently damage a winch?

Yes. Repeated overheating degrades motor insulation, solenoid contacts, and wiring, leading to premature failure.

Final Takeaway: Duty Cycle Matters More Than Advertised Pull Rating

Most UTV winch failures are caused by overheating, not insufficient pulling power.

Winch duty cycle determines whether a recovery can be completed without thermal damage, while pull rating only indicates the maximum force a winch can generate briefly. In real recoveries, heat buildup, not strength, sets the true operating limit.

A winch that stays within its thermal limits will consistently outperform a stronger winch that overheats mid-recovery.

This distinction becomes clear when comparing winches built for different recovery demands and usage patterns, in Best UTV Winch guide, where duty-cycle behavior often reveals the real difference between paper specifications and field reliability.

Duty cycle should be regarded as a safety boundary, not a performance target, especially during extended recoveries.

Continue exploring related topics:

ATVNotes is an off-road resource focused on ATV and UTV winching, recovery systems, safety gear, tires, batteries, and essential off-road equipment. Content is produced by the ATVNotes Expert Team and written from the perspective of a practical off-road recovery advisor, emphasizing real-world performance, system compatibility, and safety-first practices across trail riding, utility use, and off-road exploration.