ATV Winch Solenoid – a switch that regulates the power going to your ATV’s winch – malfunction is one of the most frequent causes; your ATV winch fails you. When this happens, it could be due to an electrical issue or a mechanical issue. Knowing the exact cause is paramount. So, how to test ATV winch solenoids is a crucial skill both for veteran and amateur ATV riders.

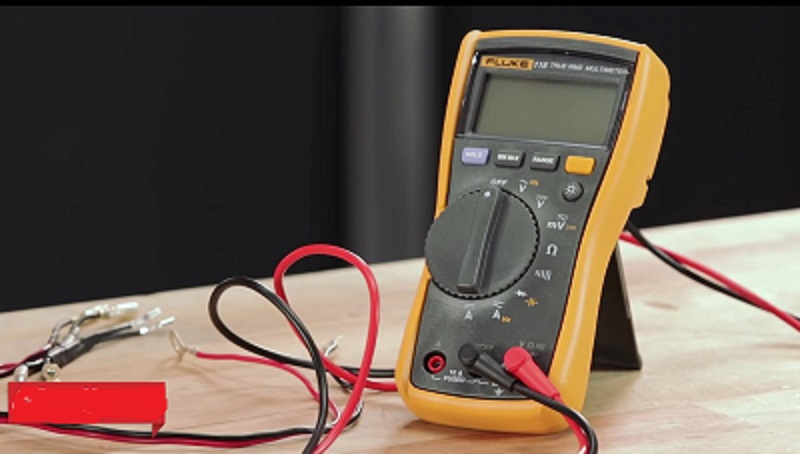

Testing an ATV winch solenoid involves checking the electrical system and its components to determine if they are functioning properly. To do this, a digital multimeter can be used to measure voltage, resistance, and current. If any anomalies are found during these tests, they should be addressed immediately as faulty ATV winch solenoids may cause safety concerns when in use.

Before jumping on the testing ground, let’s explore the reasons for winch solenoid malfunctions.

Jump To Contents

Key Reasons Why TATV Winch Solenoid Malfunction

Winch solenoid is an integral part of winching mechanism. At times, the component may malfunction, leading to serious issues for the owner. In this section, we will discuss the key and common reasons why an ATV winch solenoid might malfunction. Here you go:

Bad Electrical Connection – Rusted/Frayed/Faulty Wiring

One of the most common causes of an ATV winch solenoid malfunction is a bad electrical connection. The connection between the winch and the battery may become corroded or loose, resulting in poor power delivery to the solenoid. This can cause it to stop functioning properly or not work at all. It’s important to regularly check your winch cable connections with fuse and others for any signs of corrosion or wear and tear.

The rusted or frayed wire is a common sign of electrical short which will prevent the solenoid from functioning properly. This may lead to issues such as overheating and failure of other components in the system. Additionally, if these wires are left unchecked for too long, they could even cause a spark which could potentially lead to a fire hazard. You must inspect winch wiring and all other wirings regularly and replace any rusted or frayed wires immediately to keep your winch system running safely and efficiently.

Faulty Ground Connection of the Wiring Harness

Another potential reason for an ATV winch solenoid malfunction could be a faulty ground connection on the vehicle side of the wiring harness. If this ground connection fails, it will result in a lack of power being provided to the solenoid, causing it to not function properly or not work at all. Checking this ground connection should be included in your regular maintenance routine as well since any issues with it can affect how your ATV functions as well as impact its performance when using accessories like a winch.

To prevent this issue from occurring, all parts should be properly insulated against the ground and any exposed metal surfaces should be covered with protective coating or paint. Additionally, regular maintenance checks should be conducted on your ATV’s winching system so as to ensure that it remains functioning properly at all times.

Lack of/Low Electrical Voltage

Finally, a malfunctioning ATV winch solenoid can be caused by a lack of electrical voltage. The solenoid is an electromagnet, which requires electric power to operate. If the electricity supplied to the solenoid is inadequate, it will not be able to generate enough magnetism to actuate the switch system and release the brake mechanism. This can cause your ATV winch solenoid to become stuck in either an open or closed position, preventing the operation of the winch.

To prevent this issue from occurring, you must regularly inspect and maintain your ATV battery and charging system. Make sure your ATV battery has enough charge and that the cables connecting it to other components are clean and not loose. Replace it, if your ATV battery life is over and cannot hold charge for minimum duration.

Additionally, check for any loose connections in your wiring harnesses or corroded terminals on your starter relay or battery posts as these problems may lead to reduced charging current flow.

How to Test an ATV Winch Solenoid

If your ATV malfunctions, you need to test it to detect the faults and where they are triggered from. The testing is a bit tricky but with the process broken down into the following easy steps, you need not invest for professional help to identify the malfunctioning issue. If you are a weekend DIY warrior, you can do the test yourself in 8 simple steps: Here you go:

Tools You Need to Test with Multimeter

- A multimeter

- Jumper cables

- A.C. or D.C. power source

- Protective equipment

- Multimeter probes

- Safety equipment – eye goggles and insulated gloves (to prevent electrocution)

Disconnect the Winch from the Power Source

Disconnect the winch and its power source first. The ATV’s main battery must be disconnected too. The negative cable should be removed first, followed by the positive one. This will prevent any shock to you while testing the winch.

Locate the Solenoid

Identify the winch solenoid by visually inspecting the winch setup. The solenoid is typically a small box located near the winch motor. Take guidance from winch’s manual if needed to find the solenoid accurately.

Check for Connection Issues

Examine the connections on the solenoid for any signs of looseness or corrosion. If you find any issues, carefully clean the links and tighten them securely. This step ensures proper electrical contact and can often resolve problems related to poor connections.

Set Your Multimeter

Take your multimeter and set it to Ohms. Take the multimeter probes and set the black probe on one of the large solenoid terminals, and place the red one on the other large solenoid.

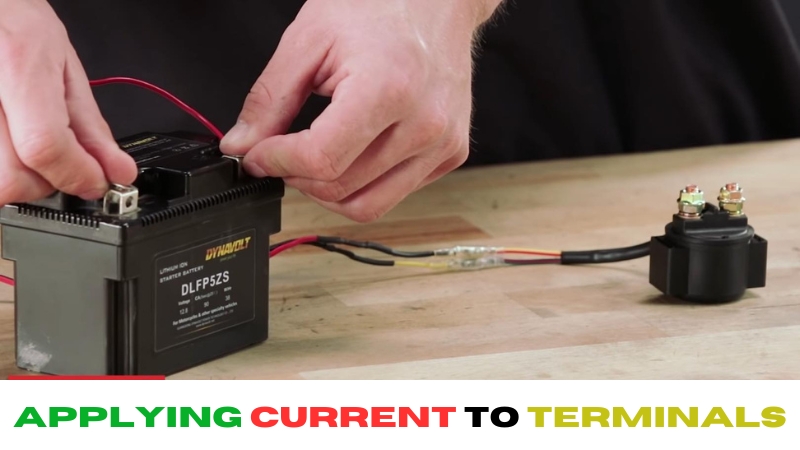

Apply Current to the Terminals

Remember that some solenoids have three terminals, which may initially look confusing. However, you will soon realize that two of them look the same, and one looks a bit different. The ones that look the same are the terminals you will be working with.

Apply current to the solenoid (you can use a car battery for this), and if you see a low Ohm reading between 0 and 1, your solenoid is working fine.

If not, you will have to change your solenoid.

Or you can run other tests to diagnose the problem as a last resort.

Continuity Test with Multimeter

Ensure Safety

Ensure you wear your safety equipment to avoid being electrocuted and set the multimeter to the Ohms setting.

Connecting Probes and Jumper Cables

Put the probes on the same as before, and ensure the connections are in proper contact. Connect one of the ends of your jumper cables with a battery’s posts or other current sources, and connect the other end with the small power supply terminals.

Diagnosing the Problem

You should hear a click sound after the battery has been connected properly. If you do not hear one, your solenoid coil is faulty, and the whole unit needs to be replaced.

However, if you hear a click sound, your solenoid coil works completely fine.

Note Multimeter Readings

Look at your multimeter results- the reading should be between 0 and 1 or even 2. If so, your solenoid is fine, and the connection is good. If the reading is O.L., you must replace your solenoid as it indicates an incomplete circuit within the solenoid, either from a bad wire or coil or something else.

Now, we will head over to our voltage test to see if the solenoid is getting or functioning with the necessary amount of volt.

Voltage Test with Multimeter

Setting Your Multimeter

Now you will have to set your multimeter to AC/ DC voltage. Most solenoids run in A.C. volts, but some do in D.C., so find out what volts your solenoid uses. If you have not already. You could check your solenoid manuals.

Applying Current

Place each of the multimeter probes on the solenoid terminals using alligator clips. Negative and positive do not matter here. Apply current the way we have mentioned previously, and you will hear a click with a reading of 12 volts, or at least in the range of 11-13 volts. This means that your solenoid is fine. If your solenoid runs in A.C., ensure your current source, such as the battery, also runs in A.C. This does not apply to the previous test.

Multimeter Reading

If the reading is not between 11 and 13, then your solenoid relay or external wiring might be at fault. This could mean that you do not have to replace the entire solenoid.

Or something crucial is damaged in the solenoid, and you will have to change the entire unit.

FAQs

What happens when an ATV winch fails?

You may have chosen the right ATV winch but it may fail you after a period of use for several reasons. And when an ATV winch fails, it can leave you stranded in the middle of a mudhole or stuck on a rock outcropping.

Without the power of the winch to help pull your ATV up and out of these difficult spots, you may find yourself caught between manually lifting and pushing your quad free and stay stranded. Regular checking of your ATV winch solenoid, ATV starter, and the like can save you from untoward situations caused by ATV winch failure.

What Purpose Does a Solenoid Serve on a Winch?

A solenoid is an electromechanical device used to control a winch. It supplies the necessary voltage and current needed to move the winch when engaged, allowing you to operate it more safely and effectively.

Also, a solenoid can be used to control the speed and direction of a winch, allowing you to control its movement with great precision.

Can a Winch Work without a Solenoid?

Running a winch without solenoid is possible, but it is not recommended. Without the aid of a solenoid, you would have to manually control the current and voltage going into the winch, which can be dangerous and unreliable.

A solenoid will provide more consistent performance, better safety features, and increased efficiency than manual operation. It is advised to use a solenoid for any winching applications.

What Can Cause a Winch Solenoid to fail?

A winch solenoid can fail due to a few different reasons. The most common causes include corrosion, faulty wiring, low voltage or current, and overloading the winch. Inspecting the winch and its components regularly can help you identify any potential problems before they cause a failure in the solenoid.

Final Words

Testing ATV winch solenoid with a multimeter is not as daunting as it may seem. All you have to do is make sure all the connections are proper and check all the readings using your multimeter. With this, you can easily diagnose problems with your ATV winch solenoid. So, whenever you test your solenoid, follow all safety protocols to ensure a safe environment. Good luck!

ATVNotes is an off-road resource focused on ATV and UTV winching, recovery systems, safety gear, tires, batteries, and essential off-road equipment. Content is produced by the ATVNotes Expert Team and written from the perspective of a practical off-road recovery advisor, emphasizing real-world performance, system compatibility, and safety-first practices across trail riding, utility use, and off-road exploration.