You’re out on the trail, deep in the backcountry, and your ATV is buried to the axles in thick, sticky mud. No problem—you’ve got a winch. You hit the switch… and nothing happens. No pull, no power, just dead weight. Chances are, your solenoid has failed, leaving you stuck in the worst possible moment.

A winch solenoid is like the command center for your winch motor. It controls the heavy electrical current needed to pull you out of trouble, and without a good one, your winch is just a fancy hood ornament.

Choosing the right solenoid for an ATV means the difference between a smooth recovery and a long walk back to camp.

Let’s break it down so you never get left hanging.

Jump To Contents

Understanding ATV Winch Solenoid

A solenoid is an electrical relay that acts as a switch, directing power from the battery to the winch motor. It allows the winch to pull heavy loads without drawing too much current through the switch, which could otherwise cause overheating or failure.

How Does a Winch Solenoid Work?

When you press the winch control switch, the solenoid engages and routes power to the motor, allowing it to spool in or out. Here’s the breakdown of what the solenoid does:

- Acts like a relay: It allows a small switch to control the high current needed to power the winch.

- Protects your switch & wiring: Without it, the control switch would have to carry all that heavy electrical load, which could easily burn it out or overheat the wires.

- Ensures safety: It prevents accidental short circuits and overheating by properly directing power.

Can you use a winch without a solenoid?

Technically yes, you can bypass the solenoid and directly wire a switch or manually connect power. A solenoid isn’t absolutely mandatory for an ATV winch to work, but it’s highly recommended—almost essential—for safe and efficient operation. But for a starter solenoid:

- It’s risky: You might overload your wiring or accidentally short the battery.

- It’s inconvenient: You’d have to manually connect and disconnect wires every time.

- It’s not durable: You’ll wear out switches or melt something sooner or later.

So, the bottomline is you can run an ATV winch without a solenoid, but it’s like riding without a helmet—it’ll work, but it’s a bad idea. The solenoid keeps things safe, clean, and easy to use.

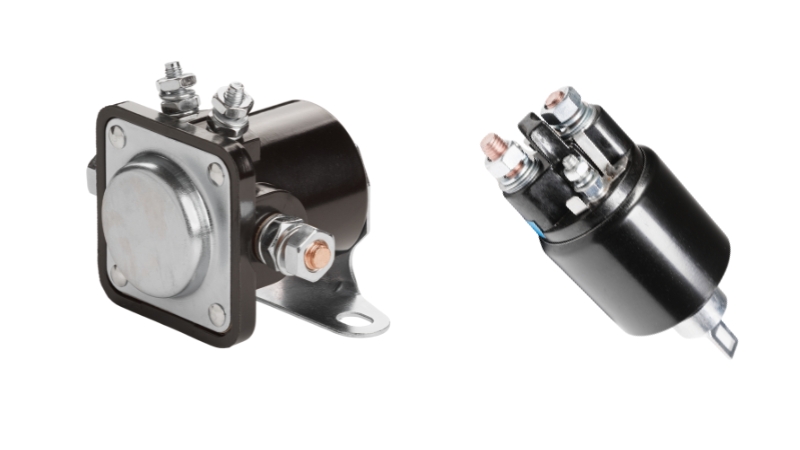

Common Types of Winch Solenoids

Continuous/Heavy-duty Winch Solenoids – Built to withstand extended winch operation without overheating. These solenoids are ideal for heavy-duty applications, such as recovery operations, industrial use, or any scenario where the winch may need to run for prolonged periods.

Their design allows them to handle higher electrical loads without failing under stress.

Intermittent Duty Solenoids – Designed for occasional or short-duration use, these solenoids are common in standard ATV winches. They are more affordable and effective for light to moderate-duty applications, but they can overheat if used continuously for long periods.

Ideal for riders who use their winch infrequently or for short bursts of pulling power.

When to Replace Your ATV Winch Solenoid?

Your ATV winch solenoid won’t last forever. Over time, exposure to harsh conditions, frequent use, and electrical wear take their toll. Knowing when and why to replace it can save you from frustrating failures when you need your winch the most.

Intermittent or Slow Operation – If your winch starts hesitating or working only sometimes, your solenoid might be failing. Electrical contacts inside may be wearing out or corroded.

Winch Only Works in One Direction – A failing solenoid can stop sending power in one direction, making it impossible to reel your cable back in (or out).

Clicking Noise But No Movement – If you hear a click but your winch motor isn’t turning, the solenoid isn’t fully engaging.

Burnt Smell or Overheating – A solenoid that’s running too hot or smells like something’s burning is on its last legs. This could indicate internal arcing or excessive resistance.

Frequent Winch Use – If you’re constantly pulling heavy loads, your solenoid will wear out faster. Heavy-duty usage means more electrical cycles, leading to wear over time.

Exposure to Water and Mud – Off-roading often means dealing with water crossings, mud pits, and rain. Even waterproof solenoids can degrade over time due to moisture intrusion or corrosion.

Preventive Maintenance – Even if you’re not having issues now, replacing a solenoid before it completely fails can prevent getting stranded when you need it most.

Recommended Read: The Ultimate Guide to Choosing an ATV Winch

How to Choose the Perfect Solenoid for Your ATV Winch

When choosing the right solenoid for your ATV winch, you have several factors to consider. Here are the key considerations to reach the right solenoid for your ATV winch.

Voltage Compatibility – ATV winches typically run on 12V solenoids, but larger setups may require 24V solenoids. Ensure the solenoid matches your winch’s voltage requirements.

Amp Rating & Power Capacity – Check the solenoid’s amp rating to ensure it can handle your winch motor’s power. Heavy-duty solenoids can handle higher amps and are better for frequent use.

Waterproofing & Durability – A sealed, waterproof solenoid is crucial for off-road and wet conditions. Look for solenoids with weatherproof housings to prevent moisture damage.

Brand Compatibility – Make sure the solenoid you choose is compatible with your winch brand. Some brands require specific solenoids, while others accept universal models. Always check fitment before buying. Trusted names like Warn, Badland, Superwinch, and Albright offer dependable options across a wide range of ATV winches.

Winch Solenoid Replacement to Opt for

When you need a replacement solenoid for your ATV winch, you have three options—OEM, aftermarket and Universal – to choose from. Each type has its advantages, depending on your budget, compatibility requirements, and intended usage.

OEM (Original Equipment Manufacturer) Winch Solenoids

When you’re looking for a replacement solenoid, OEM (Original Equipment Manufacturer) options are the gold standard. These are built by the same brand that made your winch, so they’re designed to be a perfect match—no guesswork, no adjustments.

Moreover, OEM solenoids usually offer the highest reliability and performance because they follow the original design and specifications exactly. They’re also more likely to be covered under warranty if used with the same brand winch.

The trade-off is cost—OEM parts tend to be the most expensive. But for those who use their winch often or in extreme conditions, the peace of mind and longevity can be worth every penny.

Aftermarket Winch Solenoids

Aftermarket solenoids give you more flexibility—and often a better price. These are made by third-party manufacturers and can be excellent alternatives to OEM versions if chosen carefully.

Many are built to the same or even higher standards, with features like improved waterproofing or heat resistance. Brands like KFI, Superwinch, and MotoAlliance offer quality aftermarket solenoids that can be more durable than some OEMs.

However, since they’re not made specifically for your winch, you’ll need to double-check compatibility, including voltage, amp rating, and terminal layout. With the right specs, aftermarket solenoids can be a smart upgrade or a cost-effective replacement.

Universal Winch Solenoids

Universal solenoids are the most versatile option, designed to work across many different winch brands and models. These are especially helpful if you’re not sure what your original solenoid was or if you’ve pieced together a custom setup.

That said, “universal” doesn’t mean one-size-fits-all—voltage, amperage, and wiring configurations still need to be an exact match for safe operation. Universal solenoids are often more budget-friendly and easy to find, making them a popular choice for quick replacements or field fixes.

Just take a bit of extra care to make sure what you’re buying will actually work with your system.

Top-Rated ATV/UTV Winch Solenoids

Top-rated ATV winch solenoids fall into two categories – small to mid-size load capacity & heavy-duty ones for robust capacity. The ATVNotes team has, after thorough research, made two rundowns for these two groups.

Recommended for Small to Mid-Size Winches (1500-3500 lbs)

WARN 62871 ATV Winch Solenoid – Specifically designed for WARN A2000 series winches, this OEM solenoid ensures precise fit and optimal performance. It offers reliable switching action and is built to handle rugged ATV conditions.

Perfect for users who want seamless integration with their WARN winch system without worrying about compatibility issues.

Superwinch 12V Solenoid Relay – A highly reliable solenoid that is compact, durable, and known for excellent performance. Ideal for small to mid-sized ATV winches, capable of supporting 3000-4000 lbs winching capacity.

This is a winch-specific solenoid recommended for different models of Superwinch winches. They ensure smooth operation under various conditions.

Superwinch replacement winch solenoids also offer higher capacity solenoids (for TigerShark 9500 lbs and 11500 lbs). So, check the specifications before purchasing.

Badland 3500 Winch Solenoid – Badland ZRX 12V 250A winch solenoid is suggested for this range, a cost-effective choice that offers waterproof protection and solid performance. This solenoid is great for ATV riders looking for a balance between affordability and dependability.

Road Passion offers aftermarket replacement winch solenoids of the same range for Badland winches and more.

Recommended Heavy-Duty Solenoids for Large Winches (4500+ lbs)

Warn 62135 Solenoid Kit – Built for heavy-duty applications, this solenoid is weather-resistant and designed to handle high-power winches. It ensures long-lasting performance, even in extreme conditions.

Albright 12V 500A Heavy-Duty Solenoid – This is a universal replacement option and A top choice for industrial-strength winching needs, Albright solenoids are known for their high efficiency, reliability, and superior durability. Frequently used in professional-grade winches.

X-BULL 12V 500A Winch Solenoid Relay Controller – Designed for winches ranging from 9,500 lbs to 17,000 lbs, this solenoid is sealed, corrosion-resistant, and compatible with wireless remotes.

OPENROAD 500A 12V Winch Relay Solenoid – Suitable for 8,000 lbs to 13,000 lbs winches, this heavy-duty solenoid ensures reliable performance for ATV, UTV, and truck applications.

How to Replace an ATV Winch Solenoid

So, you’ve tested your existing solenoid and confirmed it’s faulty—now it’s time to go for a replacement. You know how to choose the right one. The process is straightforward if you follow a few careful steps. Here’s how to do it:

Step 1: Disconnect the Battery

Always begin by disconnecting the negative (-) terminal of your ATV battery. This ensures safety by cutting off power to the electrical system.

Step 2: Locate the Old Solenoid

Find your existing solenoid, which is typically mounted near the battery or the winch motor. It’s a small box with several wires running into it.

Step 3: Label and Disconnect Wires

Before removing any wires, label them using masking tape or stickers so you’ll know where they go later. Then, unscrew the terminals and gently pull the wires free.

Step 4: Remove the Old Solenoid

Use a screwdriver or socket wrench to remove the mounting screws or bolts. Take out the old solenoid and set it aside.

Step 5: Install the New Solenoid

Position the new solenoid where the old one was mounted. Use the same screws or bolts to secure it firmly, keeping it away from water exposure if possible.

Step 6: Reconnect the Wires

Reconnect each wire to its matching terminal on the new solenoid using the labels you made earlier. Double-check your work against the winch solenoid wiring diagram if needed.

Step 7: Reconnect the Battery and Test

Hook the negative battery cable back up and test the winch. Run it both in and out to confirm that everything works correctly.

Recommended Read: Wiring ATV Winch Successfully

Maintenance Tips for Winch Solenoid Longevity

Keeping your winch solenoid in top shape can prevent unexpected failures and extend its lifespan. Here are some key maintenance tips:

Prevent Corrosion & Water Damage – Apply dielectric grease to the solenoid terminals to protect them from moisture, dirt, and rust. Also, consider mounting the solenoid in a location shielded from direct water exposure.

Check Wiring Regularly – Inspect all electrical connections for loose, frayed, or corroded wires. A weak or damaged connection can lead to power loss, erratic winch operation, or even solenoid failure.

Clean the Solenoid Housing – Dust, mud, and grime can accumulate around the solenoid, affecting its performance. Wipe it down occasionally to ensure smooth electrical conductivity.

Avoid Overloading & Overheating – Repeated heavy loads can strain the solenoid. Allow it to cool between heavy pulls, and avoid using a winch rated below the required load capacity.

Perform Routine Function Tests – Engage the winch periodically, even when not in regular use, to ensure the solenoid stays functional. This prevents internal components from seizing due to long periods of inactivity.

Secure the Solenoid Mounting – Loose mounting can lead to vibrations that may cause wire disconnections or internal damage. Ensure the solenoid is firmly attached to a stable surface.

Invest in the Right Solenoid for Your ATV Winch

A faulty solenoid can leave you stranded when you need your winch the most. Don’t wait for winching failure—take action now. Choose a solenoid that matches your winch’s power needs and environment.

If your current ATV winch solenoid is failing, replace it before it stops working completely. While regular maintenance and testing keep your winch system reliable, investing in the right solenoid for an ATV winch comes first.

So, ensure your ATV is ready for any challenge ahead.

Relevant Reads include:

ATVNotes is an off-road resource focused on ATV and UTV winching, recovery systems, safety gear, tires, batteries, and essential off-road equipment. Content is produced by the ATVNotes Expert Team and written from the perspective of a practical off-road recovery advisor, emphasizing real-world performance, system compatibility, and safety-first practices across trail riding, utility use, and off-road exploration.